Ok after a long hiatus (wow, longer than I thought! Other renovations took precedence.) I’m back at it.

In the interim I’ve tried a lot of the suggestions and have done some factfinding.

The PVC cap I was trying to open is not a valve, but clean out access for a well.

Still having an issue opening it. It was suggested I dig it out completely and use a heavy duty plumbing wrench and a blowtorch.

Nonetheless, I was able to “patch” water in through the pump priming faucet inlet and get sprinklers to activate. So, water came out! That’s good!

Here’s where things get strange:

I have:

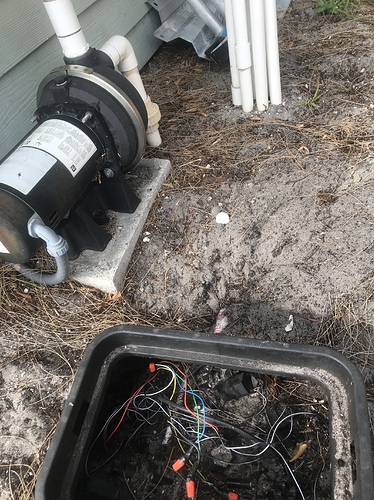

I. A Flotec pump and relay, pump connected with 1 1/4” pvc to a well (currently inoperable). The pump turns on and runs, but no water comes out.

-

1 1/4” from Pump to the indexing valve, leading to 6 3/4” PVC lines.

-

There’s a faucet between the pump and indexing valve presumably for priming. When I connect the hose to this faucet, I can get some sprinkler lines working. Seems the runs for each zone are intact minus some old heads.

-

After the indexing valve each of the six 3/4” lines has a solenoid valve. These in turn run to the various zones.

-

I haven’t been able to locate any other shutoff valve or switching in the system.

I’m in South Florida; and it seems most here have a well and indexing valve configuration. It was wired to an old intermatic way on the other side of the home indoors, not in the shed like the orbit and now the Rachio.

It looks like the solenoids were retrofitted and no one bothered to pull out the indexing valve. I guess they just ran the solenoids with a one minute break in sequence to give the valve time to switch? However, that seems really backwards and over complicated. Who knows…

Anyhow I configured the Rachio to use the electronic valves and I’m unsure how to incorporate the indexing valve or if I should just pull it?

Where does the index valve wiring come from? I haven’t been able to locate it. And how was the previous system functional with the orbit scheduler?

What I’m thinking:

- Since I’d like to have the option of using either city or well water, I’m considering T-ing off from the hose line that runs nearby the well line, and follow it with a backflow preventer and shutoff valve.

I’d like to be able to bypass the pump configuration until I have the time to address the well, so the lawn does not suffer. Also, once the well is back and running it will make for easier priming I imagine (no hose).

But, would the water also partially flow through the pump and down into the well? Would I have to have a shutoff to prevent it from going into the pump system?

Do I need the pump system even with city water? My pressure from the city is about 70-80psi at the hose head and the longest run is probably 150 feet.

I believe I’ll need a back flow preventer and thinking of just using a manual ball valve. There’s a shutoff near the pump so I can turn that off manually. Anything else I would need?

-

Pull all the solenoids out of the box, check them and organize them better in a new box. As they are now it’s incredibly crammed and it’s just about impossible to figure out what does what.

-

Remove the indexing valve entirely? But, then how to go from the 1 1/4” to the 3/4”? Anyone have a photo that could illuminate for me? Unclear how to accomplish this.

-

Install some kind of clear inline pvc piece so I can see if water is running from well? Is this called a check valve?

-

When I have time, remove that cap and assess the well. It was suggested to put muriatic acid down there to clean it out?

-

Maybe install some kind of pressure checking apparatus to adjust for differences between pump and city?

How does this plan sound to you all?

Thanks for your help as always.

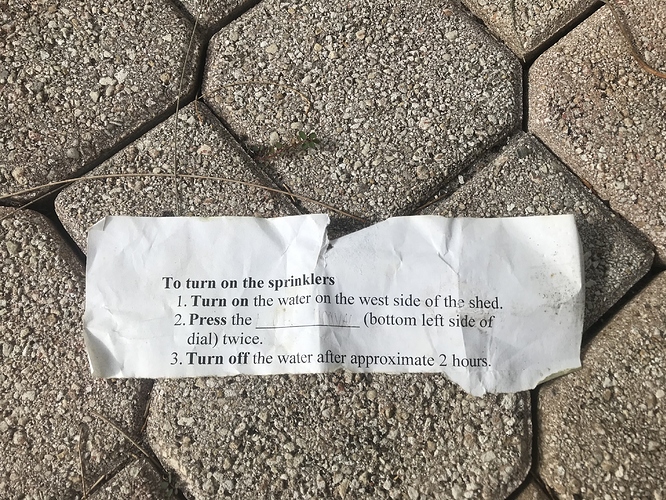

Probably who ever wrote the instructions forgot to check their compass …

Probably who ever wrote the instructions forgot to check their compass …